The most common choice of material for gasketing application is Rubber, due to its elastomeric properties, which results in high degree of deformation without permanent damage or loss of pressure. Rubber Concept manufactures gasket from.

Selection of Rubber depends upon operating condition such as temperature, contact of oil/solvent etc, life, thermal shock, durability, cost etc. Please check more detail about selection criteria here.

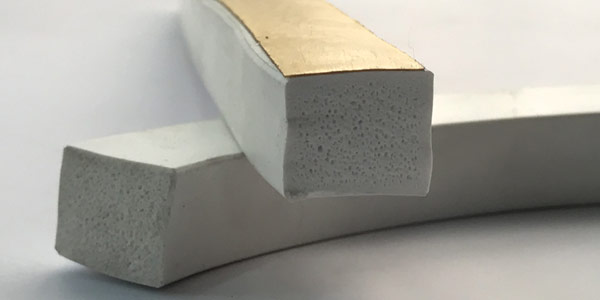

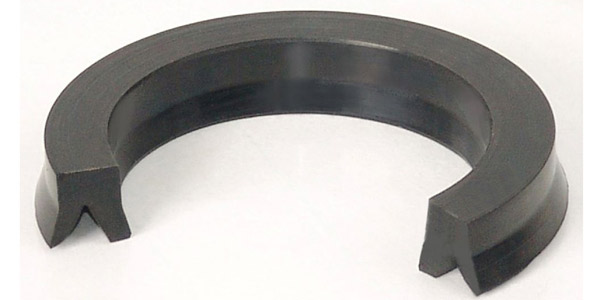

Selection of Rubber gives flexibility in designing of gasket as practically, it can be made in any shape and thickness. Rubber Concept manufacture moulded, extruded as well as precision die-punch gasket from various types of rubber. Few selected gaskets, based on geometry, can be available with pressure sensitive adhesive (PSA) backing for ease of assembly.